Around the globe, Toyota are well known for being at the forefront of process innovation; setting high standards with a high level of attention to detail. Their newest production facility in the township of Caleras de Amexhe in Guanajuato, México is no exception to this rule. We're proud to say that the AuCom CSXi has passed the Toyota test, with multiple CSXi units already installed at the new facility that is expected to begin full-time production by the end of 2019.

Each vehicle manufactured by Toyota must go through multiple tests before going to the market. One of the most common tests consists of a water shower applied to the outside of the vehicle to verify that there is no ingress of water into the vehicle.

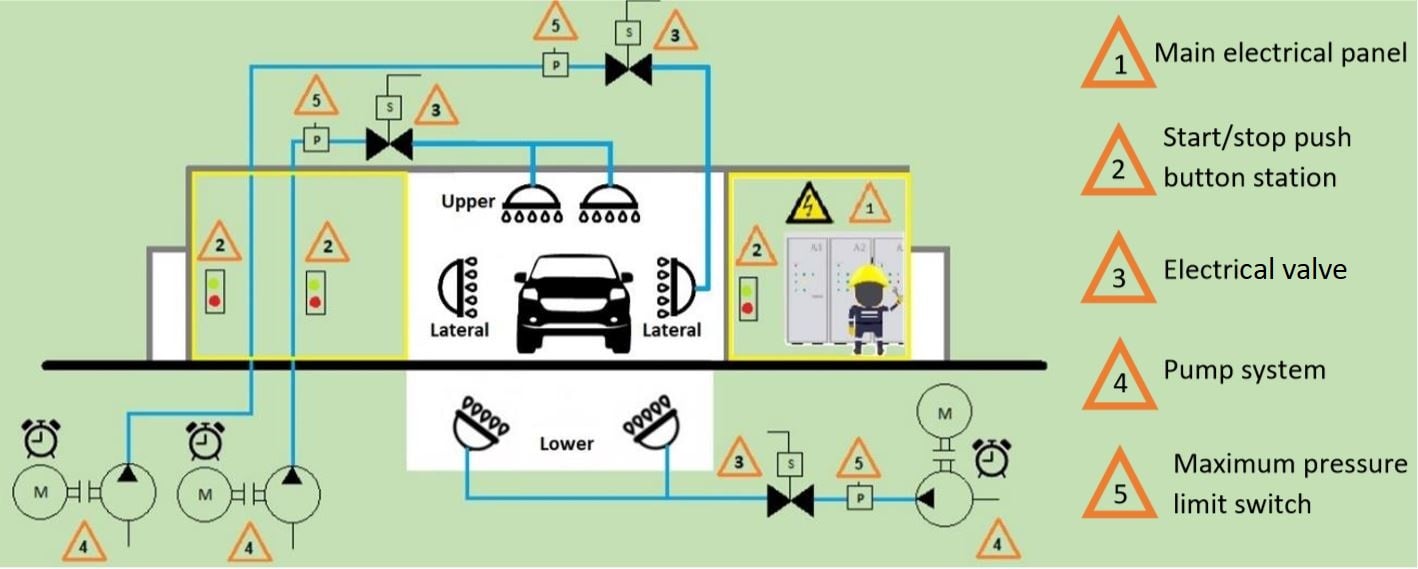

To perform this test, the vehicle is placed in a shower test room which sprays water at constant pressure through a hydraulic spray system divided into three sections: lateral (both sides), upper and lower (as shown in figure 1). Each section has an independent water distribution system, so it is necessary to implement a pumping system for each section.

However, it is known that one of the main problems that must be considered in any pumping system is the effect known as "water hammer". This effect is generated by a sudden change in the speed of the flow and can cause significant damage to pipework or hydraulic devices. The most severe effect usually occurs when pumps are started or stopped, resulting in excessive pressures that can cause severe damage.

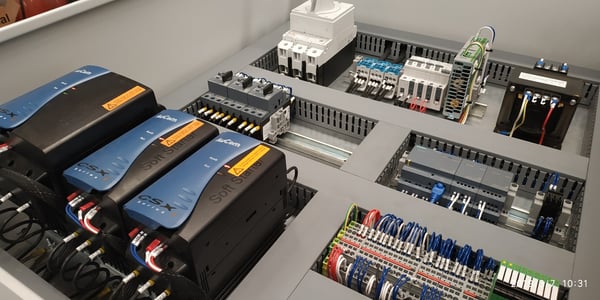

To prevent water hammer in the spray system at Toyota's new facility, Powertronics, AuCom distributor in Mexico, suggested the use of a soft starter to smoothly start and stop the pumping system. Three CSXi soft starters were used to achieve that goal, one for each section of the shower test system. For the lateral section, a CSXi-022 soft starter was used to control a pump with a 20HP motor, for the upper section a CSXi-015 controls a pump with a 15HP motor and for the lower section another CSXi-015 was used to control a pump with a 15HP motor.

With this design it is possible for the plant operators to control the acceleration and deceleration ramp times when starting and stopping the pumps, eliminating excessive pressures in the pipework and preventing water hammer, thus ensuring less downtime and longer life of the shower test system.

The plant operators at the new Toyota system are impressed with the performance and reliability of the CSXi controlled system, with Powertronics specifically noting the easy acceleration and deceleration ramp parameter adjustment by rotary switches as an ideal feature for this application.