CSXi Soft Starter

< 200A

< 200A  200 - 575V

200 - 575V

Soft start and motor overload

The CSXi provides an advanced soft start system complete with motor protection, providing a range of motor protection functions including motor overload, phase loss and excess start time.

Highlights

Compact Design

The CSXi is suitable for mounting in a switchboard or motor control centre without the need for an external bypass contactor. At only 165mm deep, it is easy to mount in shallow switchboards.

Energy Savings

CSXi is equipped with an internal bypass function to reduce operating costs. CSXi starters are 99.5% efficient during run, produce no harmonics, and are the most energy efficient solution for fixed speed applications with variable load.

Simple to Integrate

With features such as dedicated output relays to control the upstream main contactor and power factor correction capacitors, CSX soft starters are easy to integrate into complete motor control solutions.

Protection

The CSXi soft starter includes built-in motor overload protection by monitoring current and calculating motor temperature. It trips at 105% of the set Motor Trip Class, eliminating the need for an external motor protection device.

Features & Accessories

Starting Functions

- Constant current

- Current Ramp

Stopping

- Coast to stop

- Soft stop

Protection

- Motor overload

- Phase loss

- Excess start time

- Phase sequence

- Current imbalance

- Motor thermistor

- Power circuit fault

- Supply frequency

- Instantaneous overcurrent

- Bypass overload

- Communications failure

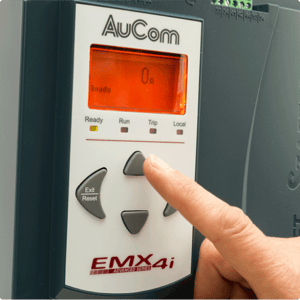

Interface

- Fixed relay output (main contractor relay)

- Programmable relay (trip or run)

- Run relay output

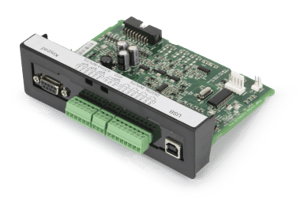

Accessories (Optional)

- Remote operator

- Modbus

- Profibus

- DeviceNet

- PC Software

- Ethernet/IP

- Modbus TCP

- Profinet

Show more

Specifications

Supply

| Mains Voltage (L1, L2, L3) | |

| CSX-xxx-V4 | 3 x 200 VAC ~ 440 VAC (+ 10% / - 15%) |

| CSX-xxx-V6 | 3 x 200 VAC ~ 575 VAC (+ 10% / - 15%) |

| Mains frequency (at start) | 45 Hz to 66 Hz |

| Rated insulation voltage | 600 VAC |

| Form designation | Bypassed semiconductor motor starter form 1 |

| Control Voltage (A1, A2, A3) | |

| CSX-xxx-xx-C1 | 110-240 VAC (+ 10% / - 15%) or 380-440 VAC (+ 10% / - 15%) |

| CSX-xxx-xx-C2 | 24 VAC/VDC (± 20%) |

Environmental

| Protection |

|

| CSX-007 to CSX-055 | IP20 |

| CSX-075 to CSX-110 | IP00 |

| Operating temperatures | - 10 °C to + 60 °C |

| Humidity | 5% to 95% Relative Humidity |

| Pollution degree | Pollution Degree 3 |

| Vibration |

IEC 60068 Test Fc Sinusoidal4 Hz to 13.2 Hz: ± 1 mm displacement |

Heat dissipation

| During start | 3 watts / ampere |

| During run | 10 watts typical |

Inputs

| Start (terminal (01) | Normally Open 150 kΩ @ 300 VAC and 5.6 kΩ @ 24 VAC/VDC |

| Stop (terminal 02) | Normally Closed 150 kΩ @ 300 VAC and 5.6 kΩ @ 24 VAC/VDC |

Outputs

| Main contactor (terminals 13, 14) | Normally Open 6 A, 30 VDC / 6 A, 250 VAC resistive |

| Programmable relay (terminals 23, 24) | Normally Open 6 A, 30 VDC / 6 A, 250 VAC resistive |

EMC Emission

| Equipment class (EMC) | Class B |

| Conducted radio frequency emission |

0.15 MHz to 0.5 MHz: < 56-46 dB (µV) 0.5 MHz to 5 MHz: < 46 dB (µV) 5 MHz to 30 MHz: 50 dB (µV) |

| Radiated radio frequency emission | 30 MHz to 230 MHz: < 30 dB (µV/m) 230 MHz to 1000 MHz: < 37 dB (µV/m) |

| This product has been designed as Class A equipment. Use of this product in domestic environments may cause radio interference, in which case the user may be required to employ additional mitigation methods. | |

EMC Immunity

| Electrostatic discharge | 4 kV contact discharge, 8 kV air discharge |

| Radio frequency electromagnetic field | 0.15 MHz to 1000 MHz: 140 dB (µV) |

| Rated impulse withstand voltage (Fast transients 5/50 ns) | 2 kV line to earth, 1 kV line to line |

| Voltage dip and short time interruption | 100 ms (at 40% nominal voltage) |

| Harmonics and distortion | IEC61000-2-4 (Class 3), EN/IEC61800-3 |

Approvals

| RCM | IEC 60947-4-2 |

| CE | EN 60947-4-2 |

| CCC | GB 14048.6 |

| EAC | TP TC 004/2011, TP TC 020/2011 |

| Marine | Lloyds Marine No 1 Specification |

| UL / C-UL | UL 508 |

Show more

Resources

Case Studies

20 Jul 20172 min read

Corus Scunthorpe Steel Mill

Corus Scunthorpe Steel Mill chooses AuCom for preventative plant maintenance.

Start Reading

22 May 20172 min read

Rice Field Flood Irrigation

AuCom helping South American rice production steam ahead. A recent project is a rice farming client on the border of Brazil and ...

Start Reading

17 Apr 20171 min read

Mirae Asset Tower

Situated just a block away from AuCom’s China office in Shanghai, engineers at Mirae Asset Tower have recently chosen CSXi soft ...

Start Reading

9 Jan 20171 min read

Cypsa Vise 'El Sauz' Jaw Crusher

AuCom partner Powertronics have applied a mix of the latest soft start technology and existing products to keep a Mexican ...

Start Reading

9 Oct 20161 min read

Clean Water Pumping in the Philippines

After several unsuccessful attempts at using soft starters on their pumping system in the past, Cabanatuan City Water District ...

Start Reading

2 Jun 20161 min read

Cape Gate Wire Draw Plant

Cape Gate (Pty) is South Africa's largest producer of wire products, manufacturing a wide range of wire products for one of the ...

Start Reading