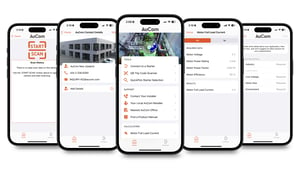

Start Here

All at your fingertips

The AuCom Start Here App puts motor control at your fingertips, empowering you to select the right starter, troubleshoot issues, and access expert support – all from your mobile device. With streamlined tools for easy model recommendations, diagnostics via QR scanning, and access to product resources, the app simplifies your motor control experience.

Highlights

Select

Using QuickPick in the Start Here app, enter your application details for an instant model recommendation and data sheet. Easily send a quote request with your application details to your local AuCom distributor.

Diagnose

Scan dynamic QR codes on AuCom soft starters with the Start Here app for instant access to starter details and the last three trip events in a readable, shareable format. Send the QR data to your nearest technician or AuCom office with a single tap.

Download

The Start Here app links directly to the library of product manuals and support resources on our website so that you have easy access to the information you need, when and where you need it.

Contact

Details for your local distributor and nearest AuCom office are stored in the app’s database. There's also a section to save contact information for your installer or designated contact, making it easy to share QR code data.

Calculate

The app also includes a range of other tools to make your life easier. Motor FLC and enclosure ventilation calculators let you make quick calculations on the go.

Connect

Connect to a Bluetooth-compatible AuCom soft starter for easy parameter control, firmware updates, event log access, and instant support.

Features & Accessories

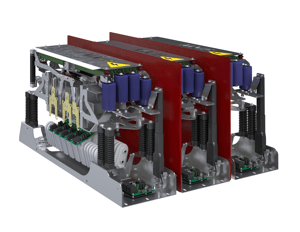

Motor Control

- Dual motor set

- Constant current and current

ramp start - Current based torque control

- TVR start

- Kickstart

- Coast to stop and TVR stop

- Slip-ring motor control

- Emergency run

Human Interface

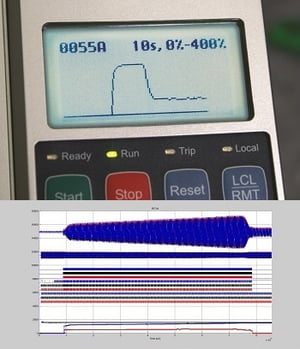

- Multi-language graphical display

- Starter status LEDs

- Date & time stamped event logging

- Real time performance graph

- Operational counters

- User programmable monitoring screen

- Fully customisable protections

- Customisable I/O operation

- Programmable start/stop

- User programmable metering screen

- Multi-level password protection

- Plug-in control terminal blocks

- Remote HMI

Advanced Diagnostics

- Internal wave form oscilloscope data logging

- Detailed event and trip logs

- Simulation modes

Protection

- Motor thermal model

- Motor thermistor

- Current imbalance

- Under/Overcurrent

- Under/over voltage

- Phase sequence

- Phase loss

- Power loss

- And more...

Input and Output Options

- Remote control inputs

(3 fixed, 2 programmable) - Relay outputs

(3 fixed, 3 programmable) - Analog output

(1 programmable) - Serial port (via comms module)

Accessories: Communication Options

- Modbus RTU

- Profibus

- DeviceNet

- Modbus TCP

- Profinet

- Ethernet/IP

- USB

Show more

Specifications

General

| Current Range | 70 - 1700 A |

Supply

| Mains Voltage (L1, L2, L3) | |

| MVE-xxxx-V02 | 2.3 kV Phase-phase |

| MVE-xxxx-V04 | 4.2 kV Phase-phase |

| MVE-xxxx-V06 | 6.6 kV Phase-phase |

| MVE-xxxx-V11 | 10/11 kV Phase-phase |

| MVE-xxxx-V13 | 13.2-13.8 kV Phase-phase |

| Control Voltage (A1, A2, A3) | 85 ~ 264 VAC or 90 ~ 350 VDC* |

| Rated Frequency | 50/60 Hz |

| Rated lightning impulse withstand voltage (Up) | |

|

2.3 - 6.6 kV

|

60 kV |

|

10/11 kV

|

75 kV |

|

13.2/13.8 kV

|

95 KV |

| Rated short-time withstand current (symmetrical RMS) (lk) | 50 kA** |

Short Circuit Capability

| Current Range | 24 A ~ 1250 A (nominal) |

| Motor connection | In-line or inside delta |

| Bypass | Integrated internal |

ANSI Protection Codes

| Code | Description | Built-in Protection |

| 48 | Maximum start time | Excess start time |

| 66 | Too many starts | Restart delay and dynamic thermal model |

| 37 | Undercurrent | Undercurrent |

| 51L | Load Increase (alarm) | High current frequency output |

| 51R | Overcurrent - jam | Excess start time, electronic shearpin |

| 50 | Overcurrent - short | Shorted SCR, electronic shearpin |

| 49/51 | Thermal overload | Thermal overload - dynamic model |

| 46 | Current imbalance | Current imbalance |

| 27 | Undervoltage | Undervoltage |

| 59 | Overvoltage | Overvoltage |

| 47 | Phase loss | Phase loss |

| 47 | Phase sequence | Phase sequence |

| 50G | Ground fault | Ground fault |

| 85 | Communications failure | Communications failure |

| 85 | Internal failure | Internal failure |

| 94/95 |

Ext. fault 1/code-1 |

Auxiliary trip A |

|

Ext. fault 1/code-2 |

Auxiliary trip B | |

| 23 |

Motor overtemperature |

Thermistor protection* |

| 49 |

Stator winding overtemperature |

Thermistor protection* |

| 32 |

Under power |

Power Loss |

Inputs on Controller

| Start (C23, C24) | 24 VDC, 8 mA approx |

| Stop (C31, C32) | 24 VDC, 8 mA approx |

| Reset (C41, C42) | 24 VDC, 8 mA approx |

| Input A (C53, C54) | 24 VDC, 8 mA approx |

| Input B (C63, C64) | 24 VDC, 8 mA approx |

| Motor thermistor (B4, B5) | Trip point > 2.4 kΩ |

Outputs

| Rating of output relays on Controller | 10 A @ 250 VAC resistive |

| 6 A @ 250 VAC 15 p.f. 0.3 | |

| 10 A @ 30 VDC resistive | |

| Outputs | |

| Relay output A (41, 43, 44) | Normally Open |

|

Output Relay B (51, 52, 54)

|

Changeover |

| Output Relay C (61, 62, 64) | Changeover |

|

Analog output (B10, B11)

|

0-20 mA or 4-20 mA |

Environmental

| Degree of Protection | |

| Power Assembly | IP00 |

| Controller | IP54 / NEM12 |

| Operating Temperature | |

|

Humidity

|

5% to 95% Relative Humidity |

| Storage Temperature | -25 °C to +70 °C |

|

Humidity

|

5% to 95% Relative Humidity |

| Operating Altitude | 1000 m ASL, higher with derating |

| Pollution Degree | IP00 |

| Vibration | Designed to IEC 60068 |

| Equipment Class (EMC) | Class A |

| EMC Emission | IEC 60947-4-2 |

| EMC Immunity | IEC 60947-4-2 |

Certification

| CCC | GB 14048.6 |

| CE | EN 60947-4-2 |

| C-UL | C22.2 No. 60947-4-2 |

| UL | 60947-4-2 |

| Marine | |

| Lloyds | Lloyds Marine No 1 Specification |

| ABS | Steel Vessel Rules 2010 |

| RCM |

IEC 60947-4-2

|

Show more