L-MVE Soft Starter

< 1700A

< 1700A  2.3 - 13.8kV

2.3 - 13.8kV

Playing it Safe

L-MVE Series Soft Starters are a robust and advanced solution designed specifically for medium voltage applications requiring high levels of safety and reliability. Equipped with comprehensive motor and load protection, the L-MVE starter offers a user-friendly graphical interface and advanced safety features, making it ideal for heavy-duty industrial and government use. Its design includes enhanced interlocks, Arc Fault protection (AFL31.5kA/1s), and short-circuit protection up to 40kA/1s, providing extensive motor control and safeguarding capabilities in a single, compact panel. Available in both single or lineup configurations, the L-Series is a well-rounded choice for complex motor control requirements

Highlights

With models suitable for currents up to 1700A and voltages up to 13.8kV L-MVE starters have your motor control needs covered.

L-Series Panel Features

| A | 2200 mm height for easier transportation |

| B | Available in both stand-alone and line-up configuration |

| C | IEC type tested |

| D | Safe operation with separate galvanically isolated low voltage section via IBT technology |

| E | Robust hinges and handles for convenient and safe closure |

| F | Built-in locking on all compartment doors as standard |

| G | Optional internal power factor correction including capacitor, vacuum contactor, fuses and inrush current limiter |

| H | A range of switching options (vacuum contactor or vacuum circuit breaker) |

| I | Corrosion resistant hot-dip galvanised steel sheets |

| J | Front panel access with optional rear panel access available |

| K | Top or bottom cable input and control wiring |

| L | Maintenance friendly design |

| M | Disconnecting switch viewing window for safer de-energising (back of enclosure) |

Fully type tested

AuCom L-Series panels are fully type tested according to IEC 62271-200:

- Short time withstand current

- Peak withstand current

- Internal arc fault (IAC Classification: AFL 31.5 kA for 1 second)

- Dielectric test on main auxiliary circuits

- IP rating

- Temperature rise tested to 50°C ambient temperature and main circuit resistance

L-Series Panel Specifications

- Rated voltage: 3.6 kV - 17.5 kV

- Rated busbar current: Up to 2000 A

- Rated short time withstand current/peak: Up to 40 kA for 1 second / 104 KA

- Internal arc fault IAC classification:

AFL 31.5 kA for 1 second - Partition classification: PM

- Loss of service continuity: LSC1/LSC2/LSC2B

- IP4X protection rating (IP54 optional)

- Altitude: < 1000 m [higher with derating]

- Ambient temperature: -10 °C -60 °C (above 50 °C with derating)

- Colour painting: RAL7035 (other colours optional)

MVE Soft Starter Features

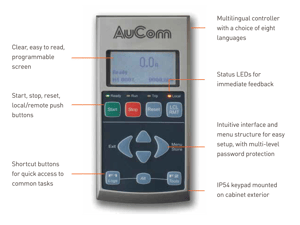

Medium voltage installations are complex enough without making the starter hard to use as well. MVE is packed with features designed to make your life easier, now powered by AuCom’s next-generation S2 controller. Simple, plain-language feedback and an intuitive full-colour HMI make it easy to understand exactly what the soft starter and motor are doing, without the need to look up codes or interpret complex data.

Built-in monitoring and indicators, along with extensive on-board input and output functionality and flexible expansion, reduce the need for auxiliary equipment, saving space and simplifying installation. Real-time graphs of motor operating performance and current clearly illustrate how your motor is performing, while advanced diagnostics and event history support confident commissioning and faster troubleshooting. No fuss, no trouble, just a smoother start in every sense.

The MVE with S2 controller delivers clear, easy-to-understand feedback on soft starter operation and events, combining advanced control capability with the straightforward usability medium voltage applications demand.

MVE Soft Starter Features

Medium voltage installations are complex enough without making the starter hard to use as well. MVE is packed with features designed to make your life easier, now powered by AuCom’s next-generation S2 controller. Simple, plain-language feedback and an intuitive full-colour HMI make it easy to understand exactly what the soft starter and motor are doing, without the need to look up codes or interpret complex data.

Built-in monitoring and indicators, along with extensive on-board input and output functionality and flexible expansion, reduce the need for auxiliary equipment, saving space and simplifying installation. Real-time graphs of motor operating performance and current clearly illustrate how your motor is performing, while advanced diagnostics and event history support confident commissioning and faster troubleshooting. No fuss, no trouble, just a smoother start in every sense.

The MVE with S2 controller delivers clear, easy-to-understand feedback on soft starter operation and events, combining advanced control capability with the straightforward usability medium voltage applications demand.

| Feature | Benefit |

| Quick Application Setup | Easy commissioning |

| Plain-language Menus and Feedback | No trip code lookups and reduced operator error |

| Full-colour Graphical HMI | Clear, intuitive visibility of motor and starter status |

| Simulation Mode | Fast and easy testing during installation and commissioning without the need for a mains supply or motor |

| Flexible Starting and Stopping Control | Smooth, controlled motor accelration and decelration across a wide range of applications |

| Dual Motor Set |

Allows two different starting and stopping motor data sets |

| Advanced Thermal Modelling |

Dynamically calculates motor temperature to determine safe starting conditions |

| Real-time Performance Visualisation | Clear, real-time graphs of motor performance and current provide instant insight into motor behaviour |

| Advanced Diagnostics | Recorded waveforms and event data support faster fault identification and reduced downtime |

| Advanced Event Logging and Waveform Capture | Improved visibility during commissioning, operation and fault conditions |

| LV/MV Isolation via IBT Technology | Isolates the control system and HMI from the MV power section for a safer working environment |

| LV Motor Test | Enables factory testing without the need for a medium voltage motor or supply |

| Secondary Injection Testing | Allows full testing of motor protections using external test systems |

| Complete Motor Protection | Ensures safe operation even in demanding applications |

| DOL+ Mode | Protects the motor even while operating in bypass mode |

| Expandable Controller Architecture | Easily scales as application requirements change |

| Built-in Connectivity and Secure Wireless Access | Simplified commissioning, monitoring and maintenance |

Protection Functionality

| Description | Built-in Protection | Eq. ASI Code |

| Maximum start time | Excess start time | 48 |

| Too many starts | Restart delay and dynamic thermal model | 66 |

| Undercurrent | Undercurrent | 37 |

| Overcurrent - jam (Locked rotor, load increase) | Instantaneous/time-delay overcurrent | 50/51/51R |

| Overcurrent - short (short circuit) | Instantaneous/time-delay overcurrent (stage 2) | 50/51 |

| Checking or interlocking relay ` | Shorted SCR | 3 |

| Thermal overload | Thermal overload - dynamic model | 49/51 |

| Current imbalance | Current imbalance | 46 |

| Undervoltage | Undervoltage | 27 |

| Overvoltage | Overvoltage | 59 |

| Phase loss | Phase loss | 47 |

| Power loss | Power loss | 32 |

| Ground fault | Ground fault | 50G |

| Mains frequency | Frequency check, frequency variation | 81 |

| External communications failure | Communications failure | 85 |

| Internal communications failure | Internal failure | 85 |

| Ext. fault 1/code-1 | Auxiliary trip A | 94/95 |

| Ext. fault 2/code-2 | Auxiliary trip B | 94//95 |

| Motor overtemperature | Thermistor protection* | 23 |

| Stator winding overtemperature | Thermistor protection* | 49 |